Advanced Food Safety Essentials/ Pre-requisites/ GMPs

Like basic food safety fundamentals, pre-requisites and GMPs, some specific food safety essentials provide solid support to advanced food safety management systems.

Ideally these fundamentals are not different than basic food safety pre-requisites but due to their nature, these require significance and extra diligence. Food business operations sturdy grip and control on these specific programs may reflect management commitment and may indicate food safety culture.

There might be many more but looking at the customer requirements, global regulatory requirements, and GFSI benchmarked schemes’ requirements, for our valued customer we have chosen eight advanced pillars and building blocks (e.g., crisis management, food defense, food fraud, allergen management, environmental monitoring program, food plant sanitation, high risk process/ products management, and sanitary design).

Crisis Management

Food Defense

Food Fraud

Allergen Management

Environmental Monitoring

Sanitation Management

High Risk Process/Areas Products Management

Sanitary Design

Crisis Management

Crisis: A crisis is an incident or unplanned and unwanted event or series of events that significantly interrupts the normal flow of business or threatens organizational ability to operate. In crisis situations, events are mostly sudden which cause major disturbances and catastrophic conditions and may trigger a feeling of fear, threat and uncertainly amongst the employees. Crises have the potential to make the environment unsafe, damage the infrastructure, and the brand. It may also affect the reputation.

GOAL OF CRISIS MANAGEMENT – RISK PERCEPTION TO CRISIS MANAGEMENT

CRISES MANAGEMENT PLAN

A crisis management plan outlines how your business will react if a crisis occurs. Its key purpose is to establish methods and established criteria and assigned roles to manage crisis situations. The purpose of the plan is to instill a well knitted proactive program that’s based on the principles of prevention, preparedness, resilience, and sustainability.

Crisis doesn't occur spontaneously it has dimensions and, in many cases, has signals and indicators. A lot could be understood and done before the crisis.

Our proposed Process of Crisis Management

PHASE 1 - CRISIS SIGNAL DETECTION

PHASE 2 - PROBING AND PREVENTION (PROBING REFERS TO LOOKING FOR RISK FACTORS)

PHASE 3 - CONTAINMENT - CRISIS RESPONSE AND MANAGEMENT.

PHASE 4 – RECOVERY

PHASE 5 – LEARNING - POST-CRISIS AND RESOLUTION

LEARNING - POST-CRISIS AND RESOLUTION

Post-crisis. All great crises must come to an end. But that doesn’t mean they won’t reoccur, especially if companies don’t undertake this final, post-crisis stage. During this phase, companies will take the opportunity to look back and reflect. They create a post-mortem to see what went wrong, which helps them think of ways to better prepare for the next crisis. It’s also when companies begin fulfilling the commitments they made while the crisis was still raging.

Crisis Management and GFSI Schemes

All GFSI recognized schemes require to establish a well knitted food safety crisis management

and business continuity plan. This plan must be tested at least once a year.

Food Vision offers following services to cater these requirements

- Crisis Management Training – Learning Crisis management and its implications

- Crisis Management System – Coaching and Consulting on Plan development and implementation

- Crisis Management – Program baseline audit / gap assessment

- Crisis Management – Current program review

- Crisis Management – Gap Assessment to know crises

- Crisis Management – Challenge Test to meet GSFI requirements

Food Defense

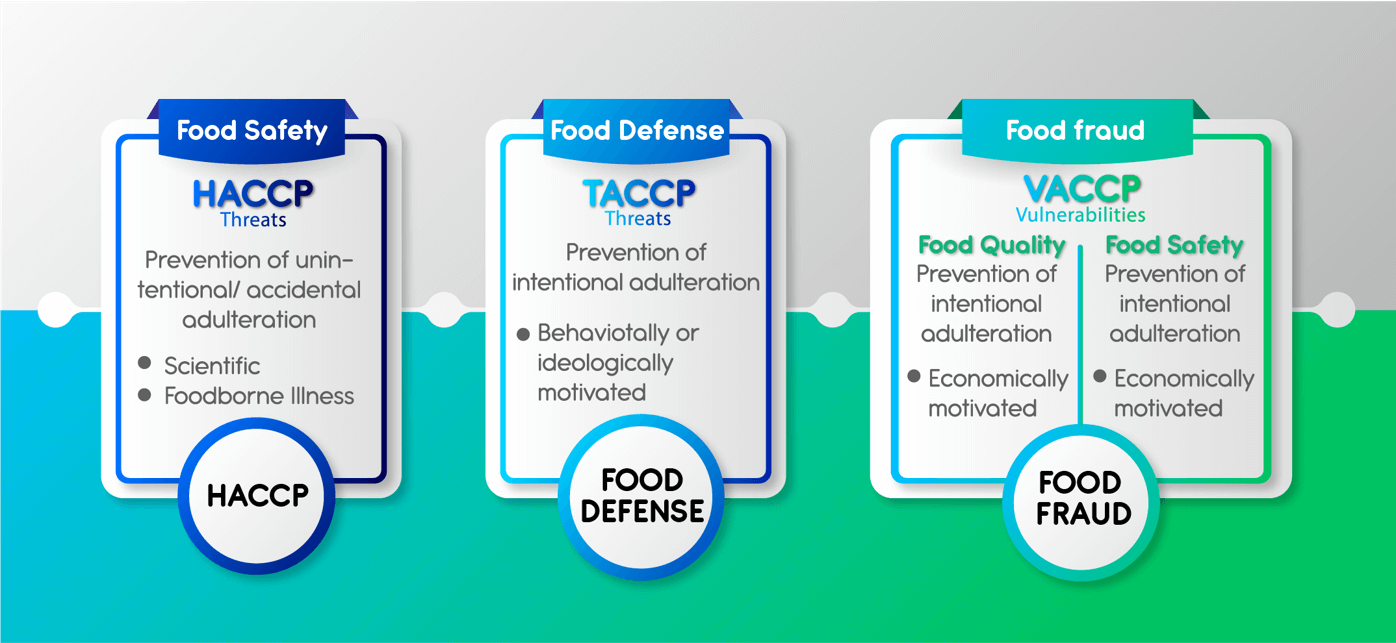

Food Defense is the outcome of efforts to protect food from acts of intentional adulteration. Its the protection of food products from contamination or adulteration intended to cause public health risk. Its the protection of food products from intentional contamination or adulteration by biological, chemical, physical, or radiological agents.

Food Defense and Advanced Food

Safety / GFSI Benchmarked Standards

Food Defense is one of the essentials in advanced food safety manage

ment systems. Likewise, its one of the integral requirements under all

GFSI benchmarked food safety management.

Food Vision offers following food defense related services

Food Defense - Food Vision scope of Service.

- Initial Gap Analysis / Vulnerability Assessment

- Food Defense Program Development and Solutions

- Food Defense Verification Audits

- Troubleshoot program failures

- Food Defense Training and Education

- Food Defense Program Challenge Exercises

Food Defense Verification Audits and Challenge Test Service

We offer services to perform an independent food defense challenge test for you operation to meet FSMA / GFSI Benchmarked Food Safety Certification requirements.

Ask a Food Defense Expert – Explore Your OptionsFood Fraud

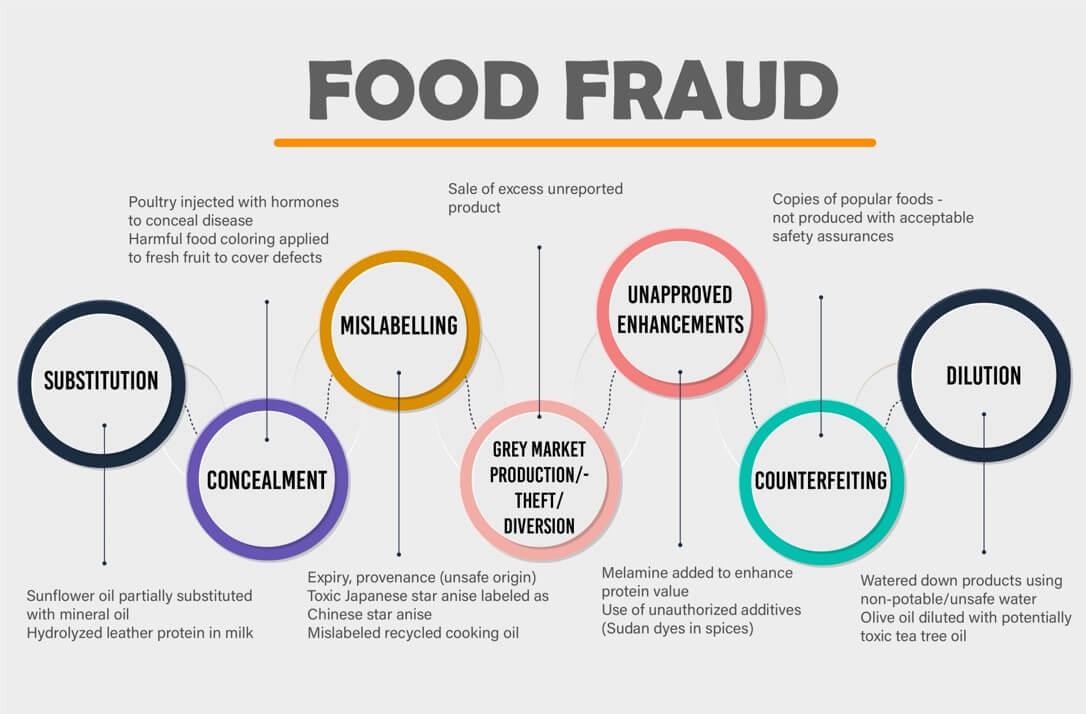

Food Fraud is Economically Motivated Adulteration (EMA). As per FDA, economically motivated adulteration (EMA) occurs “when someone intentionally leaves out, takes out, or substitutes a valuable ingredient or part of a food”.

EMA also occurs when someone adds a substance to a food to make it appear better or of greater value. As per CFIA, Food fraud may occur when food is misrepresented.

Though the food fraud focuses on economic motivation and the monitoring gain is the key focus but at time, it can pose serious health risks if adulterating materials have a possibility of unidentified allergens

or hazardous materials.

There are some common types and avenues of food fraud.

- Substituting

- Dilution

- Mislabelling

- Making false claims or misleading statement

- Counterfeiting

As per the FDA, and CFIA among the most common reported food fraud incidents are about the following product groups.

- Honey/ Maple Syrup

- Olive Oil,

- Dairy,

- Seafood,

- Juices,

- Spices,

Food Fraud is one of the key elements in GFSI recognised food safety management schemes (e.g., SQF, BRC, IFS, FSSC 22000 and others).

These schemes require to develop and imple-ment food fraud policies and procedures and perform a food fraud vulnerability assessment for all the inputs especially ingredients, raw ma-terials, and additives.

A vulnerability assessment, or Vulnerability Assessment and Critical Control Points (VACCP), is a type of assess-ment that evaluates the vulnerabilities within the supply chain, limiting the likelihood of you using fraudulent material and products.

Food Fraud and GFSI Schemes

Food Fraud is one of the key elements in GFSI recognized food safety management schemes (e.g., SQF, BRC, IFS, FSSC and others). These schemes require to develop and implement food fraud policies and procedures and perform a food fraud vulnerability assessment for all the inputs (especially ingredients, raw materials, and additives).

A Vulnerability assessment, or Vulnerability Assessment and Critical Control Points (VACCP), is a type of assessment that evaluates the vulnerabilities within the supply chain, limiting the likelihood of organizations using fraudulent material and products.

A food fraud identifies vulnerabilities to food fraud and explains how those vulnerabilities were

identified. The food fraud program is required to offer mitigation strategies where and take

measures where higher level of vulnerabilities

is possible.

Food Vision solutions division offers following food fraud expert services

- Food Fraud - Training Workshops on understanding Food Fraud

- Food Fraud - Food Fraud and Vulnerability Assessment – Program development, Procedure writing

- Food Fraud - Development of food fraud program

- Food Fraud - Food fraud vulnerability Assessments

- Food Fraud Program and Vulnerability Assessment Review

- Food Fraud – Site-specific Vulnerability assessments

- Food Fraud – Review of existing policies and existing vulnerability assessments review

How to do right and safeguard your business from food fraud?

Allergen Management

Around the globe, millions of individuals have reported food allergies and may experience adverse reactions to products that have allergenic food ingredients. These allergenic reactions may be from mild to severe and may be life threatening if medical help is not readily available. Food allergies may be deadly and as of today, there is no true cure for food allergies.

Symptoms of allergic reactions can include:

- Hives

- Flushed skin or rash

- Tingling or itchy sensation in the mouth

- Face, tongue, or lip swelling

- Vomiting and/or diarrhea

- Abdominal cramps

- Coughing or wheezing

- Dizziness and/or light-headedness

- Swelling of the throat and vocal cords

- Difficulty breathing

- Loss of consciousness

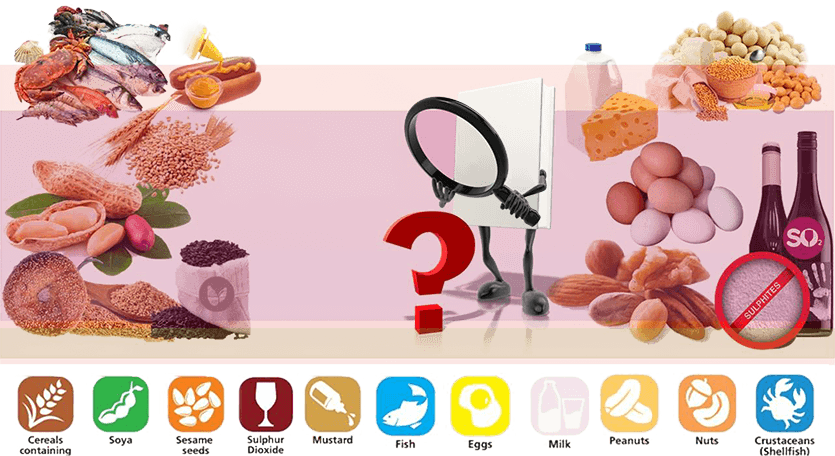

Food Allergens varies in different parts of the world. Food allergens are almost always proteins except some food constituents, or some additives which are known to pose allergenic (allergy-causing) risks.

EU Declared Allergens

There are 14 allergens recognized as the most common and potent causes of food allergies and intolerances across Europe. The allergens, as listed in EU FIC’s Annex II, are:

Cereals containing gluten: namely wheat (including specific varieties like spelt and Khorasan), rye, barley, oats, and their hybridised strains) and products thereof

- Crustaceans and products thereof (for example prawns, lobster, crabs, and crayfish)

- Egg and its derivatives

- Fish and its derivatives

- Peanut and its derivatives

- Soybeans and its derivatives

- Milk and its derivatives (including lactose)

- Nuts: namely almond, hazelnut, walnut, cashew, pecan nut, Brazil nut, pistachio nut, and Macadamia nut (Queensland nut) and their derivatives

- Celery and its derivatives

- Mustard and its derivatives

- Sesame seeds and its derivatives

- Sulphur dioxide and sulphites (at concentrations of more than 10mg/kg or 10mg/L in terms of the total SO2 which are to be calculated for products as proposed ready for consumption or as reconstituted according to the instructions of the manufacturers)

- Lupin and its derivatives

- Molluscs and products thereof (for example clams, oysters, scallops, snails, and squid)

FOOD Allergens and GFSI Benchmark Schemes

Food allergens management is among the key elements of any food safety management system including GFSI benchmarked schemes. Food Vision offers comprehensive solutions for allergen management in food business operations. Our scope of service includes but not limited to.

- Food Allergen Program, Policies and Procedures Development

- Food Allergen Risk Assessment

- Allergen Program Monitoring, Verification and Validation

- Allergen management strategies, and available testing techniques

- Allergen Troubleshooting

- Learn concepts around food allergens in your operation

- Understanding requirements for the allergens in the country of production and sale of your products.

- Allergen labeling – around the globe.

- Your supplier obligations in supporting your allergen program

- Learn how to manage your allergen management challenges to through enhancing your organization culture

Environmental Monitoring Programs

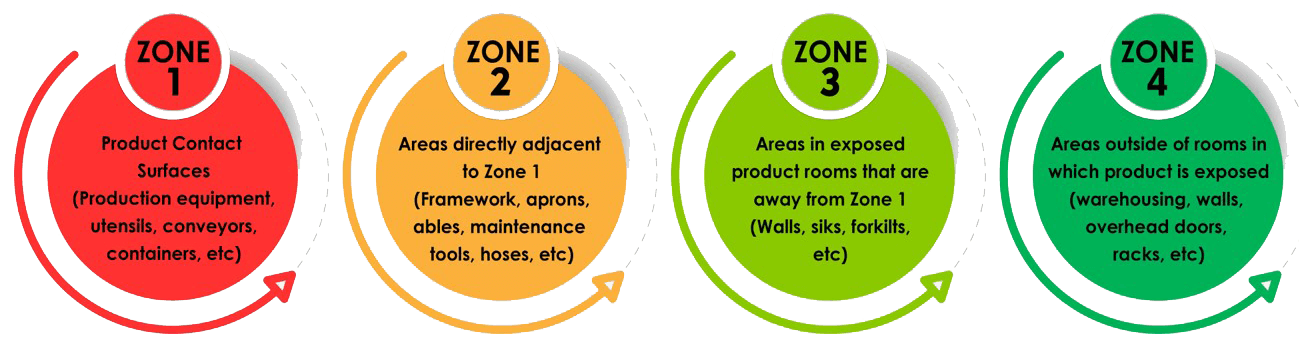

The ultimate goal of food safety is to produce safe and wholesome food products. It aims to prevent illnesses and outbreaks through adoption of preventive controls. Pathogens are the key focus of food safety. Products are the outcome, but food manufacturing operations and facilities are the environment in which materials, work in progress and finished products are handled and stored.

The hygiene and sanitary conditions of these environments play a vital role in providing safe and healthy atmosphere. The health of food plant environment is reflected by the prevalence of pathogens and unsanitary condition indicators. The monitoring of food plant atmosphere with this perspective is called environmental monitoring.

An environmental monitoring program (EMP) will assess the effectiveness of the overall hygienic practices in a facility. The EMP can help to reduce internal deviations, customer complaints, risk of recalls, risk of regulatory non-compliance, extend product shelf life, streamline production, and increase customer satisfaction.

An effective Environmental Monitoring Program (EMP) is a blessing as it indicates problems which could travel to the product and make it unsafe.

EMP and GFSI Benchmarked Schemes

FDA’s-FSMA, CFIA’s-SFCA, and All GFSI recognized food safety management schemes and standards require a risk based EMP developed and in place. Its mandated more for high risk ready to eat products than lower risk products.

To meet your Environmental Monitoring Program goals – Our experts can help.

- How to Develop and Implement an effective EMP?

- Developing concepts to understand risk based Environmental Monitoring?

- Developing concepts to understand what to test, why and how often and to finalize master EMP testing schedule?

- How to understand indicator organism and applicable pathogens prevalent in your food operation?

- How many samples and best sampling points?

- Right Sampling Techniques

- EMP - Process Mapping

- Master Sampling Plan and testing plan

- How to Trouble shooting when results are positive?

- Deviation Protocols in difference Zones.

- Validation Sampling if the results are positive

Our experts can also review your current program and advise changes to avoid issues in your upcoming customer audits, regulatory audits, or third-party audits.

Ask an EMP Expert

Sanitation Management

Effective Sanitation of food contact surfaces is always a challenge especially in high paced and high-risk environment. Sanitation is one of the FSMA suggested preventive controls.

WHY SANITATION?

Effective Sanitation of food contact surfaces is always a challenge especially in high paced and high-risk environment. Sanitation is one of the FSMA’s suggested preventive controls and CFIA’s – Safe Food for Canadian Act – SFCA’s Essentials.

Sanitation Management Program Challenges - Our experts can help.

- Coaching and Training on understanding Basic to Advance sanitation concepts and challenges

- Learn how to Develop and Implement an effective Sanitation Plan.

- Developing concepts to understand risk-based Sanitation Management.

- Developing concepts to understand what to test, why and how often and to finalize Master Sanitation and Testing Schedule.

- Lean to understand important indicator organism and applicable pathogens prevalent in your food operation.

- Explore how many samples and best sampling points?

- Right Sampling Techniques

- Effective Master Sampling Plan.

- Explore strategies to trouble shoot when results are positive and your team struggles?

- Deviation Protocols in difference Zones.

- Validation Sampling if the results are positive

Managing High Risk Processes and Products

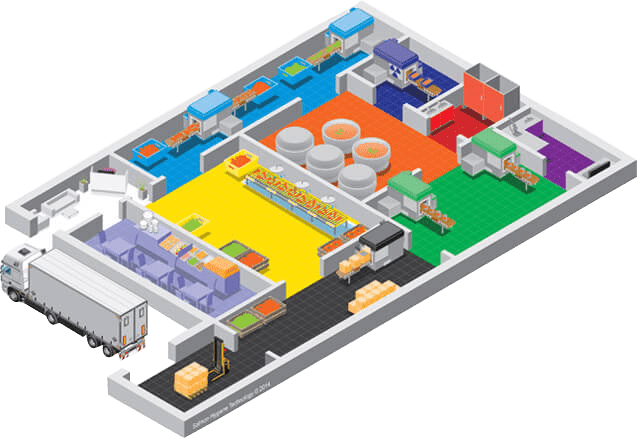

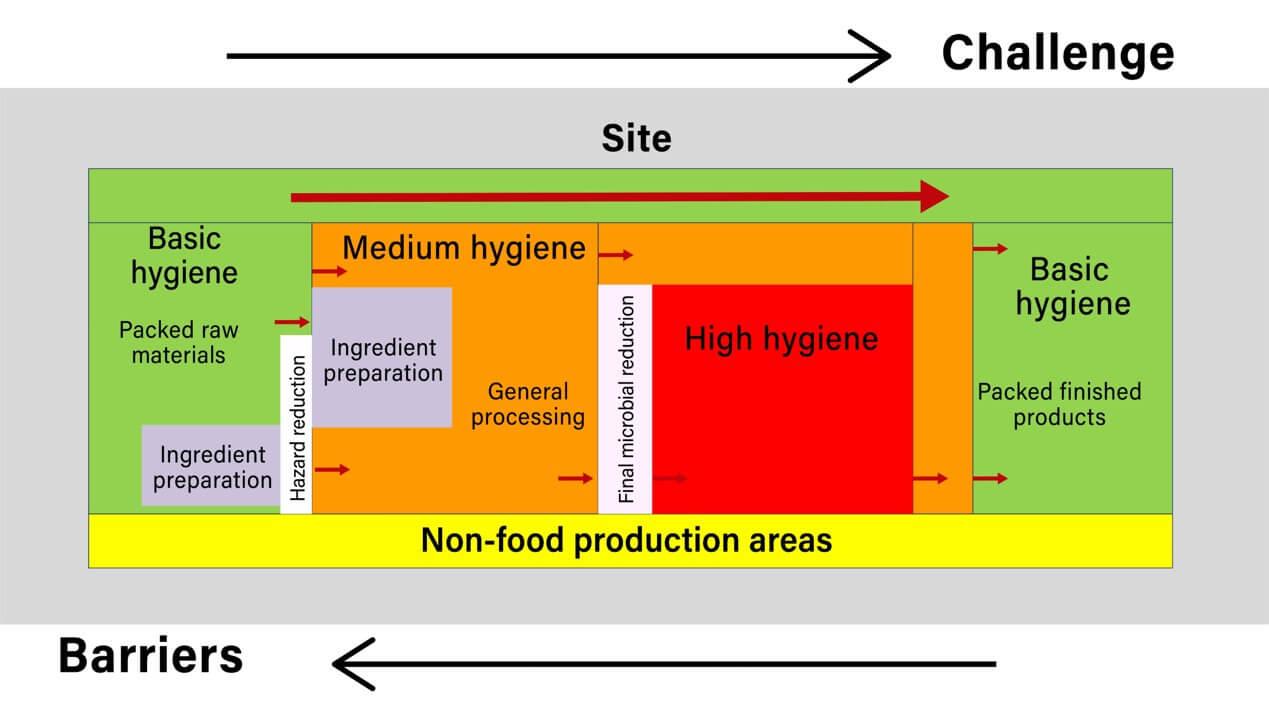

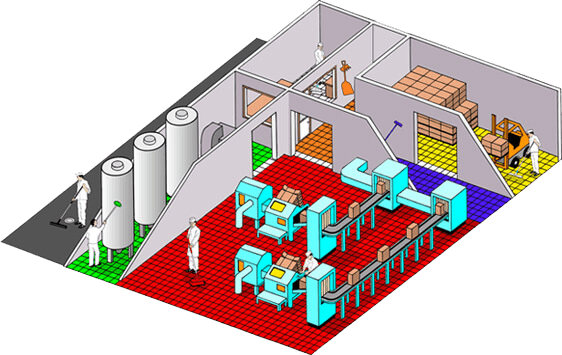

RTE foods that support the growth and multiplication of pathogenic bacteria that could be harmful are known High risk foods. To avoid issues, complaints, and outbreaks, it is imperative to handle and store high risk foods separately from raw foods to prevent the risk of cross contamination. The environment and processes that handle such RTE shelf stable foods after any CCP that ensures regulatory compliance due to its nature are usually high-risk processes.

High Risk Foods - RTE foods that support the growth and multiplication of pathogenic bacteria and could be harmful are known as High-risk foods. To avoid issues, complaints, and outbreaks, it is imperative to handle and store high risk foods separately from raw foods to prevent the risk of cross contamination.

High Risk Processes - The environment and processes that handle such RTE shelf stable foods after any CCP and may ensure regulatory compliance due to its nature are usually high-risk processes.

In addition to golden principles of clean, separate, cook, chill, to ensure safety of high-risk operations, all, or some of of the following practices may be necessitated.

- Employee, Materials and Logical Process Flow

- Separate areas for handling raw and clean materials

- Effective Temp control for temp sensitive activities and storage

- Color coding in the areas, utensils, and PPEs.

- Physical segregation compared to scheduling

- Dedicated utensils, tools, and utensils.

- Separation of Functions

- Controlled process flow

- Dedicated staff

- Area changeover

- Pathogen monitoring

- Effective Sanitation Controls

- Ongoing review of Trends

- Effective validation of controls

Ask an Expert to understand and overcome your high risk operation’s challenges

Sanitary Design / Hygiene Engineering

Sanitary design is a set of standards and conditions related to food hygiene of buildings, premises, equipment, and Processes. Food plants must adopt sanitary design principles to prevent physical, chemical, and biological contamination of food. Its one of the prerequisites and building blocks for a well designed and safe food plant as adherence to hygienic design ensures to eliminate any type of direct and indirect contamination risk posed to foods, regardless of the source.

As per the principles of Sanitary Design the surfaces and structures must comply with the following requirements.

- Made of compatible materials.

- Design cleanable to a microbiological level.

- Accessible for inspection, maintenance, cleaning, and sanitation

- No product or liquid collection:

- Hollow areas should be hermetically sealed:

- No niches

- Sanitary operational performance:

- Hygienic design of maintenance enclosures.

- Hygienic compatibility with other plant systems:

- Validate cleaning and sanitizing protocols

Like food contact surfaces and equipment design, Food plant fabric, internal an external design and flow also contribute towards achieving food safety. That’s why building construction and zoning principles should be understood and implemented. These may include flow of activities, sufficient lighting, design of floors and drains, segregation, and control of high-risk processes.

Our experts provide training, gap assessment and consultation on sanitary design requirements for food plants.

Ask an expert